Operational efficiency is often compromised in the absence of readily available experts

Staff turnover and lack of structured tools make training challenging and short-lived

The absence of precise guides leads operators to act by trial and error, slowing down even the simplest diagnoses

Common faults are not intercepted in time, causing waste, delays and avoidable downtime

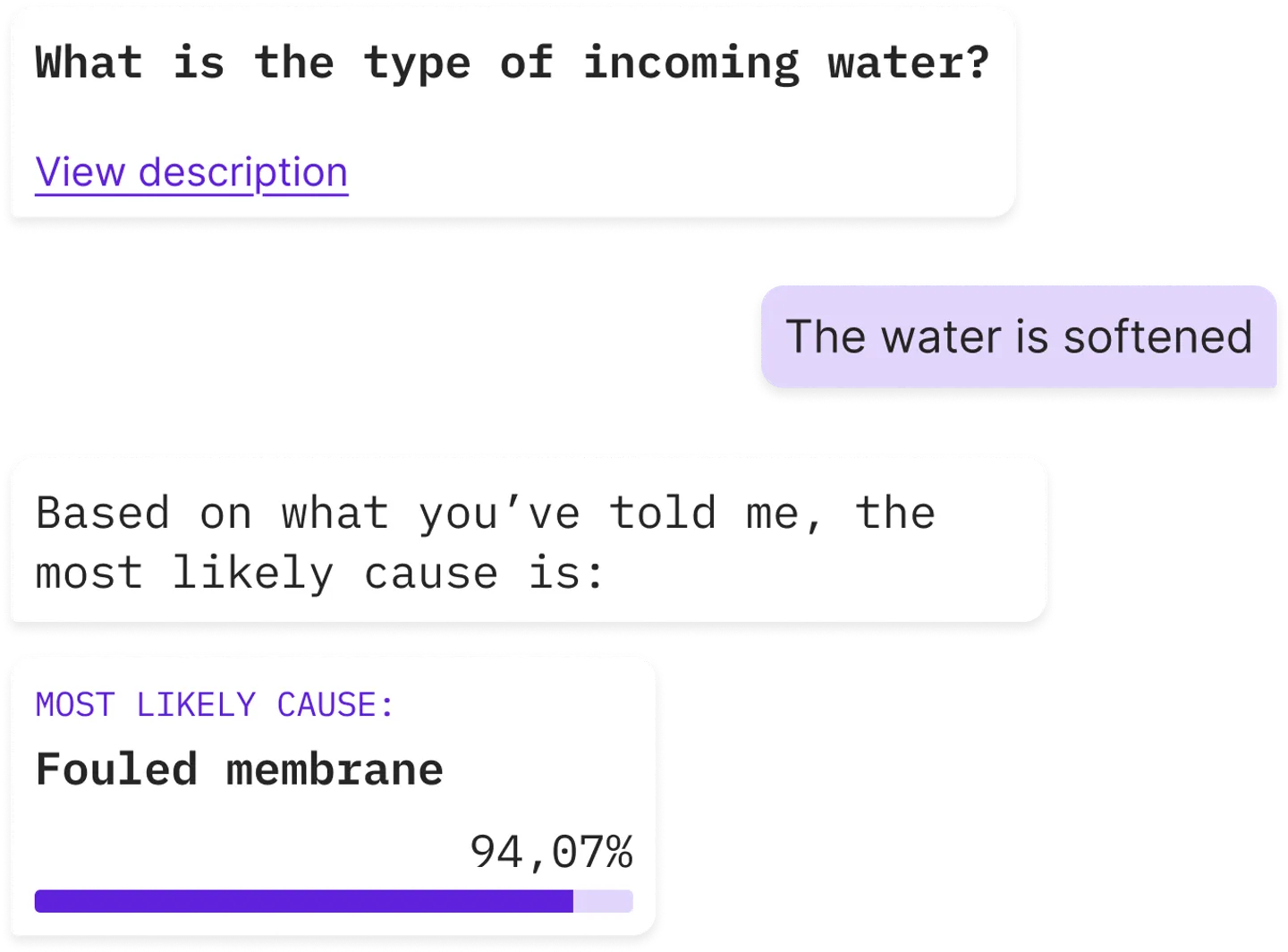

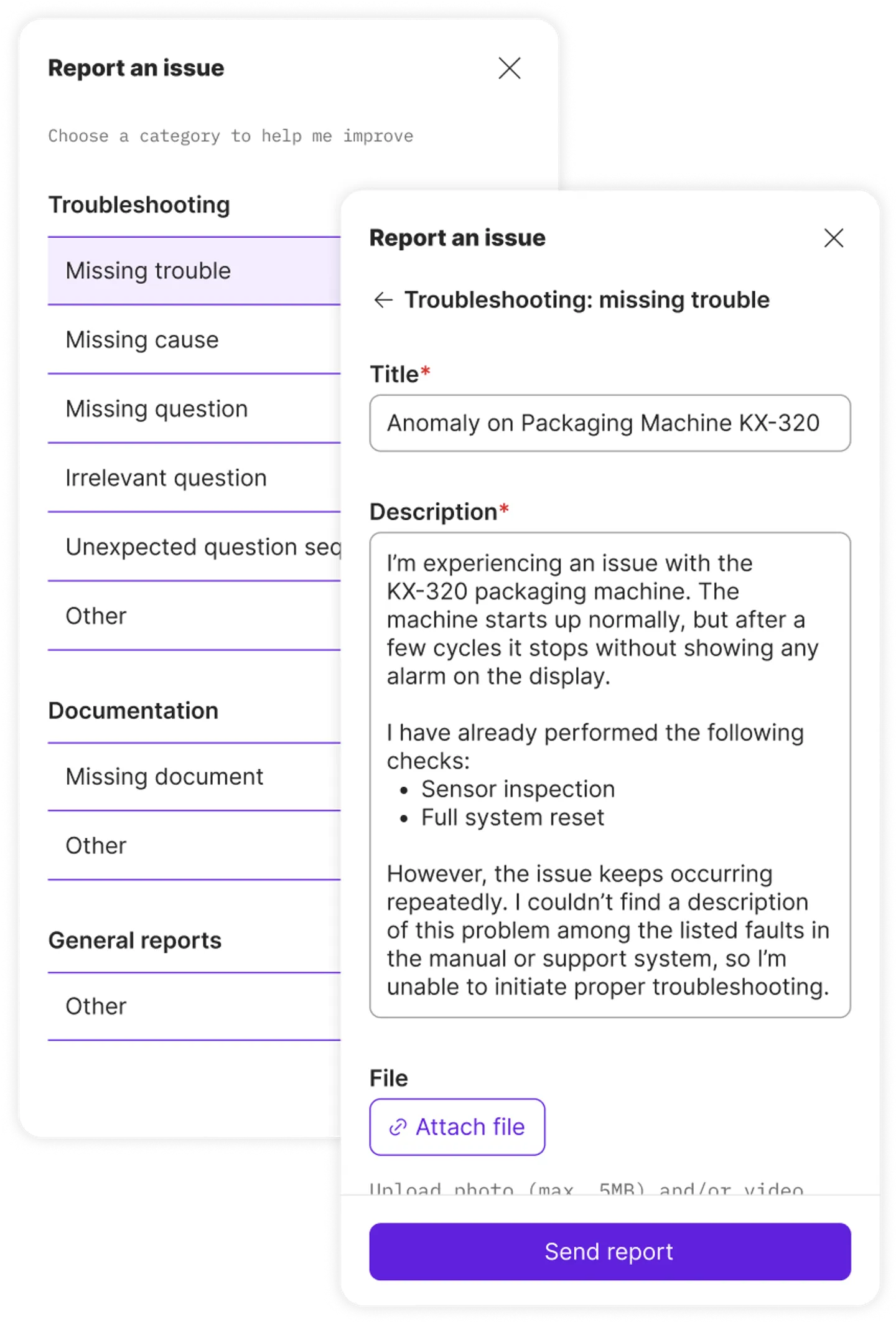

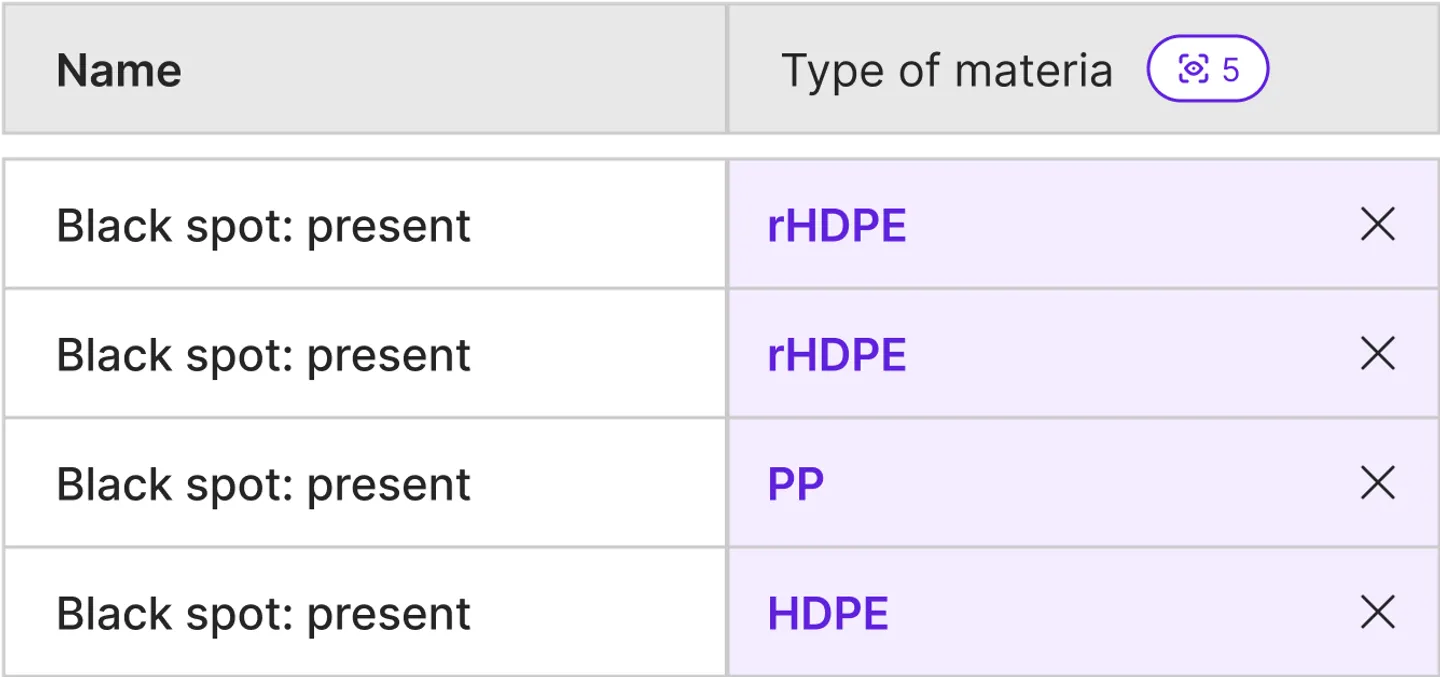

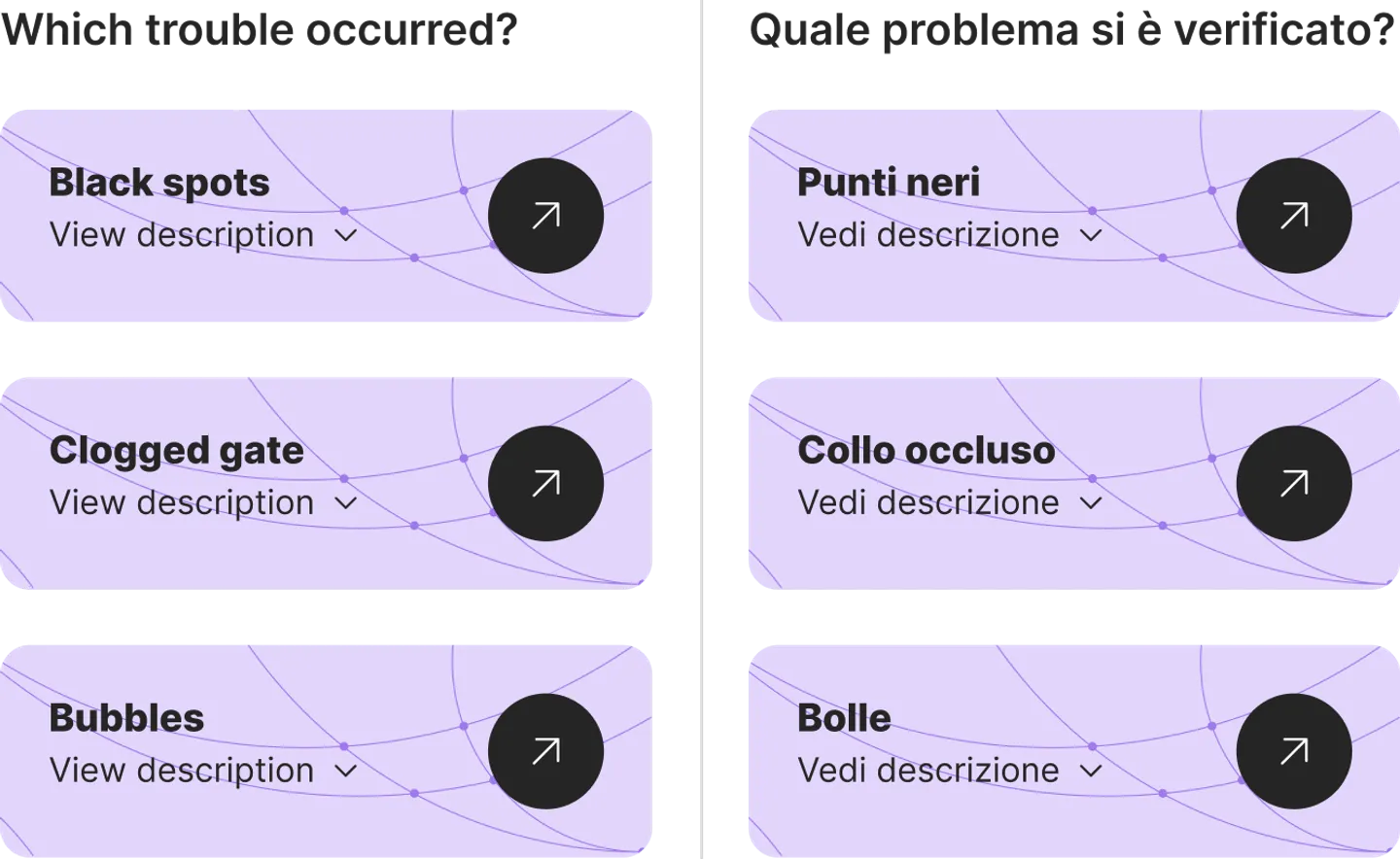

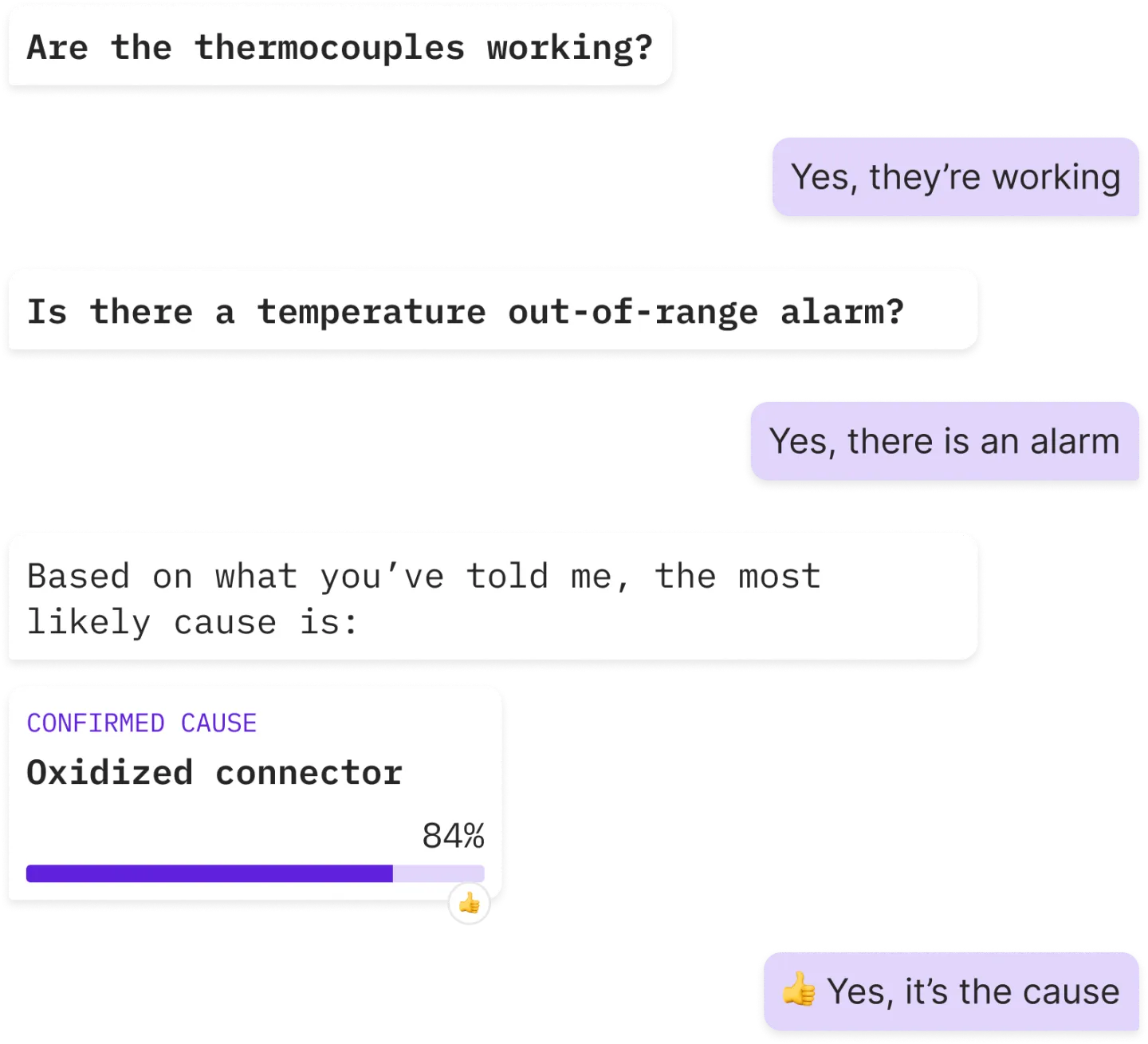

TROUBLESHOOTING

Meti expertly guides you through any anomaly and allows you to quickly resolve process issues.

PROCESS OPTIMISATION

Leverage digital knowledge to ensure maximum production efficiency, eliminating waste and machine downtime.

PLANNING

Rely on reliable data and accurate forecasts to create precise and reliable plans

NEW OPERATIONS

Exports the knowledge of the parent company to each plant, ensuring that the experience of the best technicians is accessible anywhere in real time

TRAINING

Train your staff with real cases and practical exercises, monitoring progress

TEAM ONBOARDING

We help you focus your knowledge

During the training day, you will learn to map internal expertise: we will guide you through conducting interviews and building knowledge graphs using our proprietary method.

We go through the first interviews together

We will accompany you during the first interviews, helping you articulate problems and causes. Together, we will build the initial models until you become autonomous in mapping simple cases.

We make the work available to production

We will plan the operational release together so that Meti integrates into your organisational infrastructure.

We stand by your side in complex cases

Even after you have achieved autonomy, you can count on us to support you in handling complex cases.

A product by AISent ©2025

Via Pascoli 14 – 24020 – Gorle, Bergamo – Italy

Tax Code / VAT No. IT04287240164 – Share Capital €40,000.00